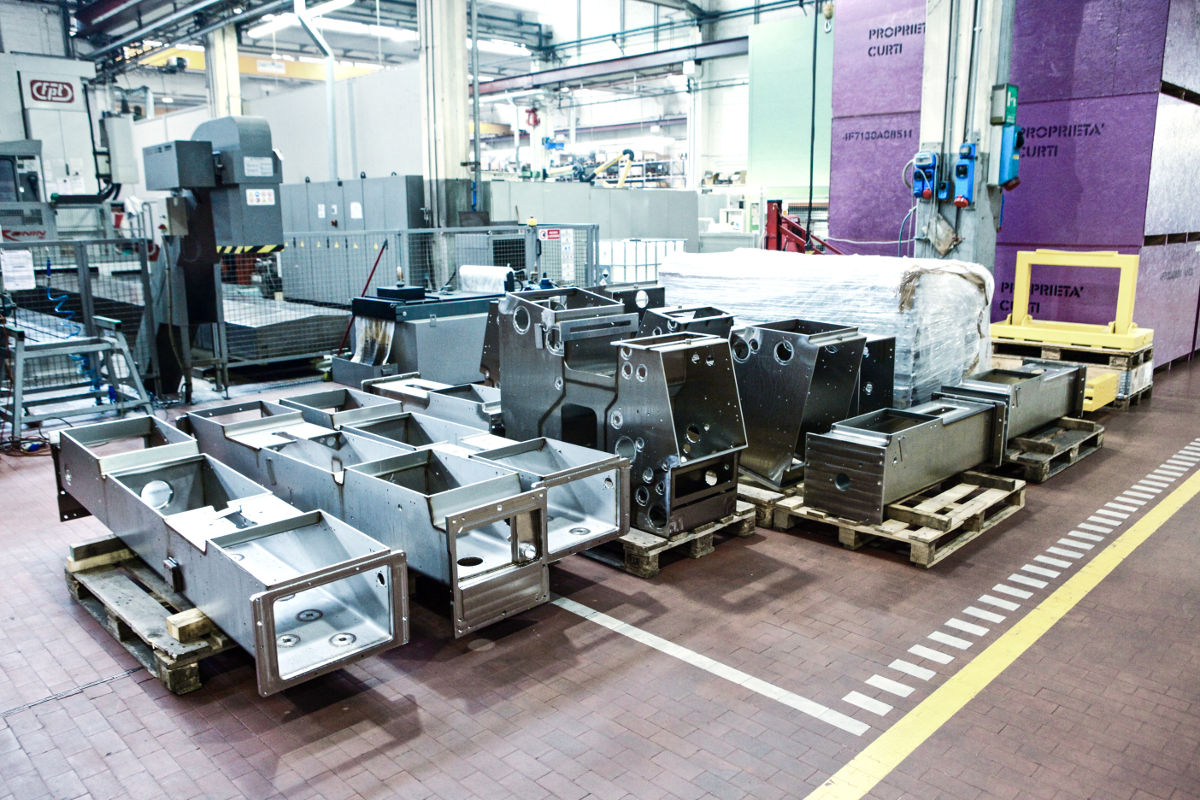

Manufacturing

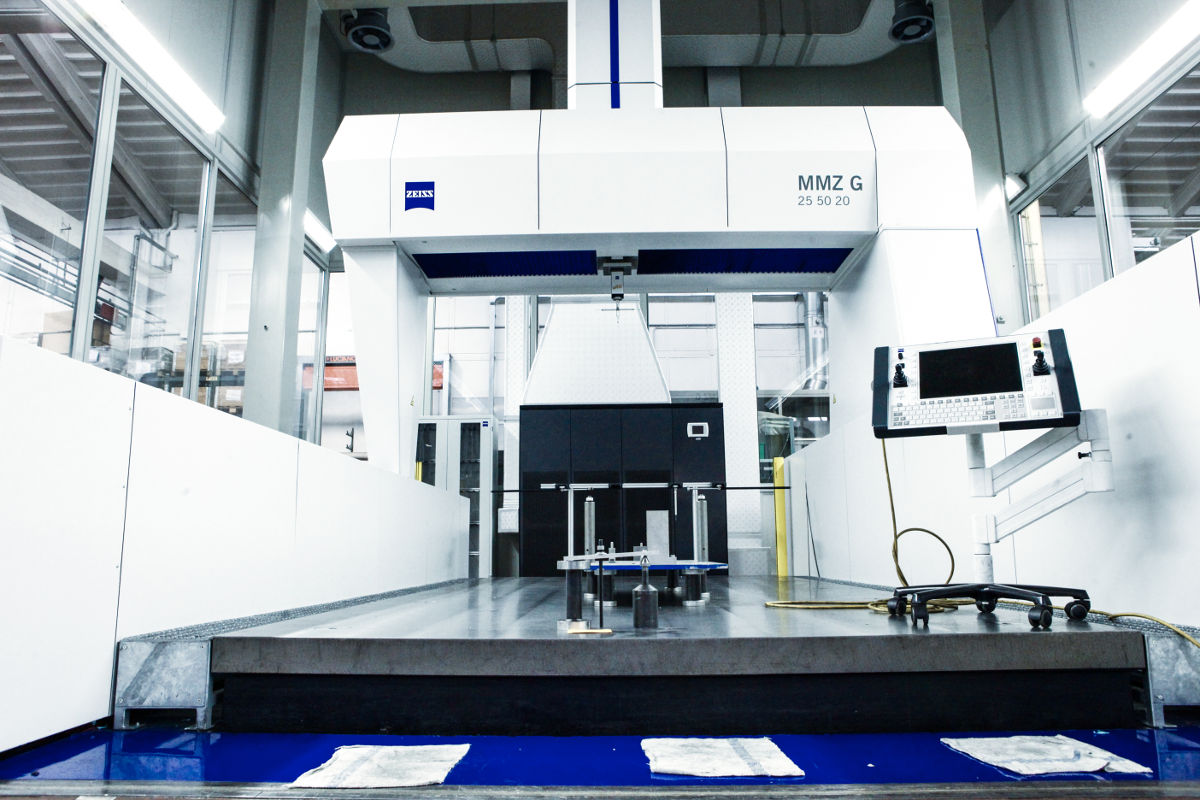

A pioneer in the use of the first numerical control machine tools, over the years CURTI has continued to enhance its technological assets in the field of machine tooling processes on noble materials, such as stainless and special steels, aluminium alloys, pure titanium and titanium alloys, through the introduction of modern machines with large operating fields and five-axis machining. To complete its supply offer, the company has measuring rooms equipped with high-precision coordinate measuring machines.

The machine fleet, composed of various machining centres, allows mechanical machining with an operating range of up to 10,000 mm with a universal bi-rotational head and operating ranges of up to 3,300 mm with a 5-axis head.

Quality control is divided up in air-conditioned measuring rooms, with the use of over 2000 instruments that are periodically checked.

Special and large-scale checks are provided through the use of CMC ZEISS for three-dimensional measurements.

The company has specially tailored processes for the heat treatment of light alloys and surface cleaning and deoxidation treatments in preparation for welding processes, as well as finishing processes such as the passivation of stainless steels and chromate conversion coating of aluminium and its alloys.

It has qualified systems and personnel for the welding of aluminium and titanium alloys, as well as of stainless and ballistic steels, with TIG, MAG and MIG processes.