CURTI Aerospace has been making mechanical components for the defence and aeronautic industries for over 40 years and supporting customers in the management of the entire production cycle, from the purchase of raw materials to quality control and non-destructive testing.

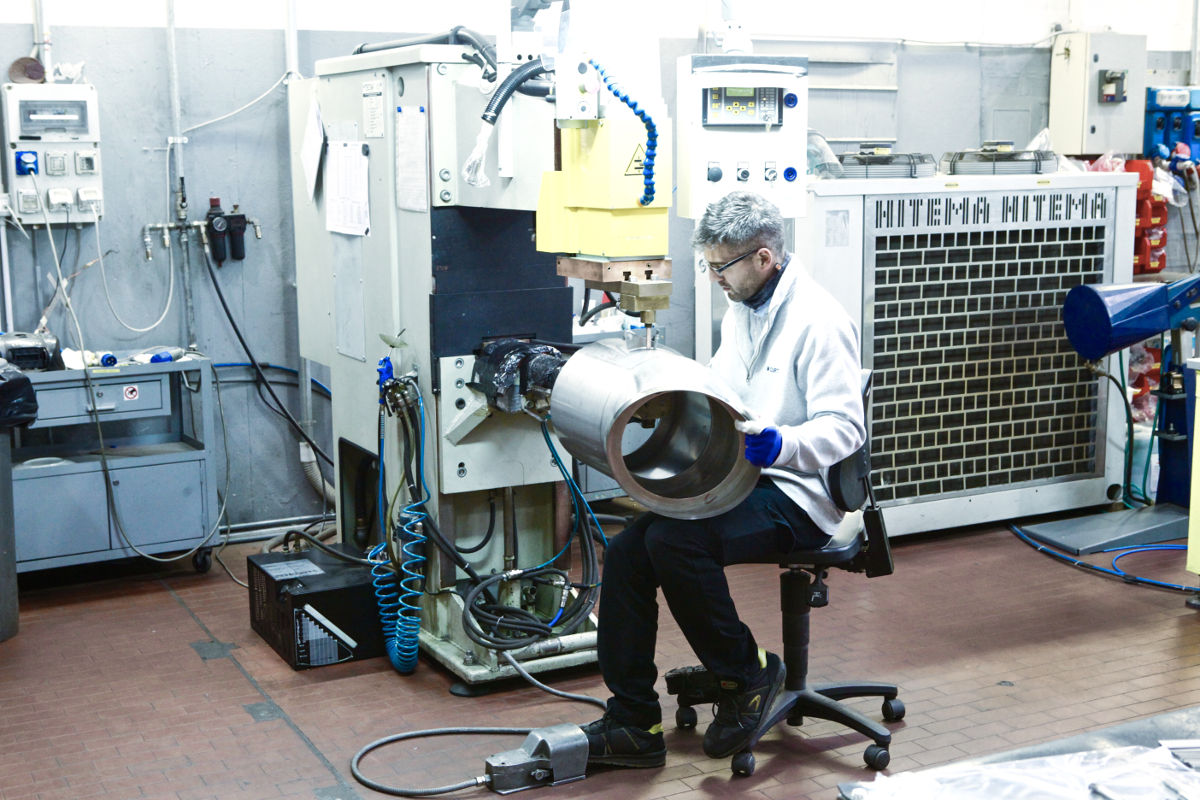

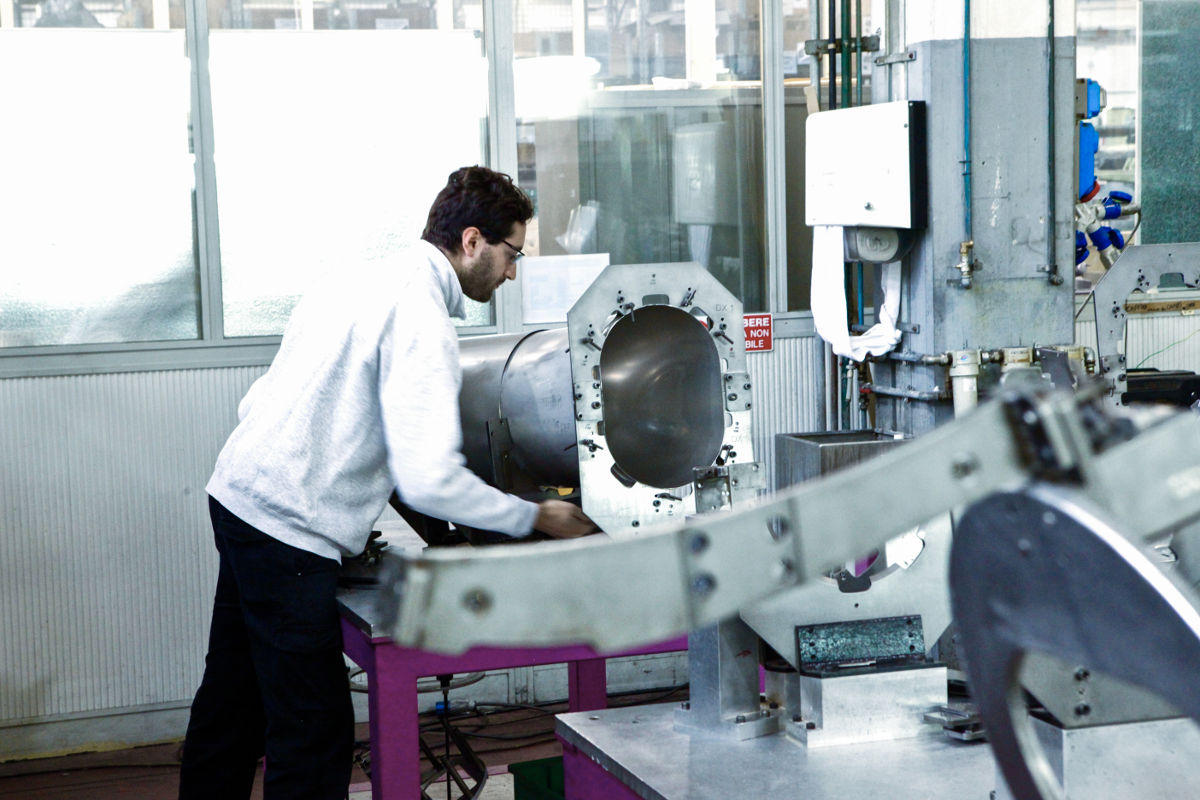

We are known for our high level of specialisation in the TIG and Resistance welding of Al, Ti, Cr-Ni and Inconel alloys, as well as in the welding of steel.

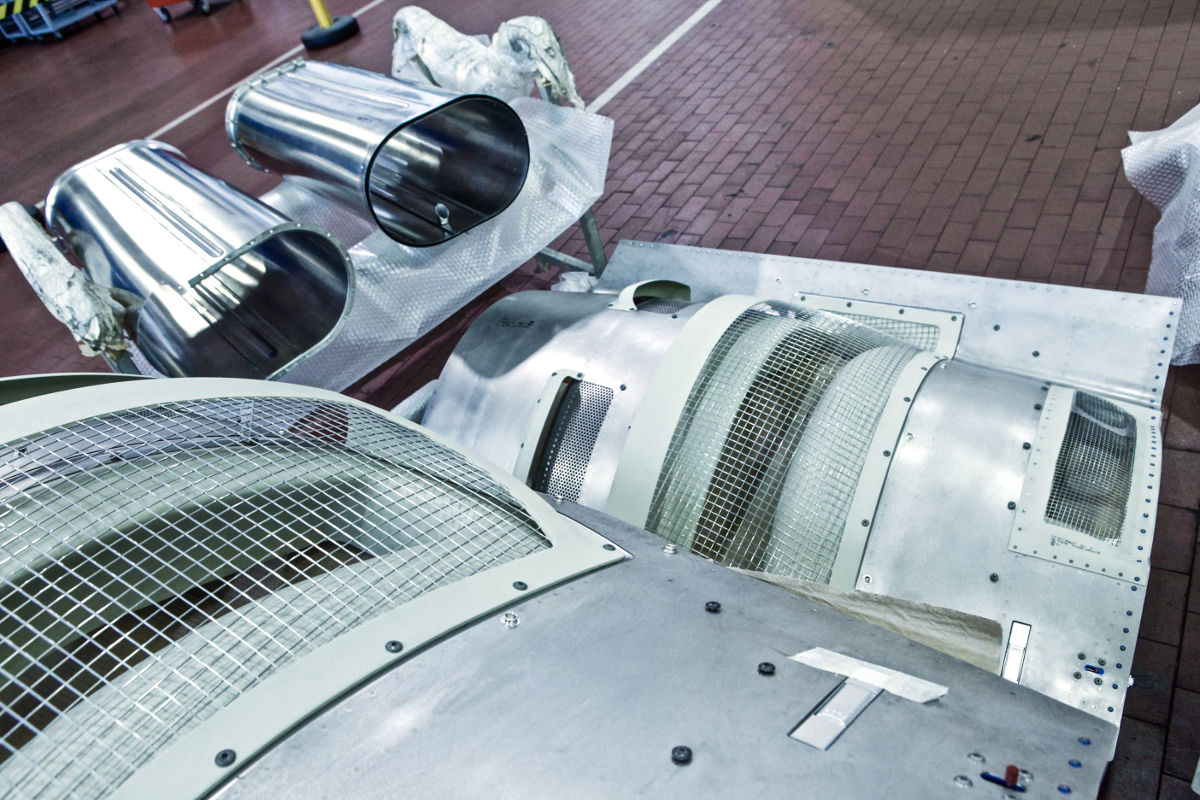

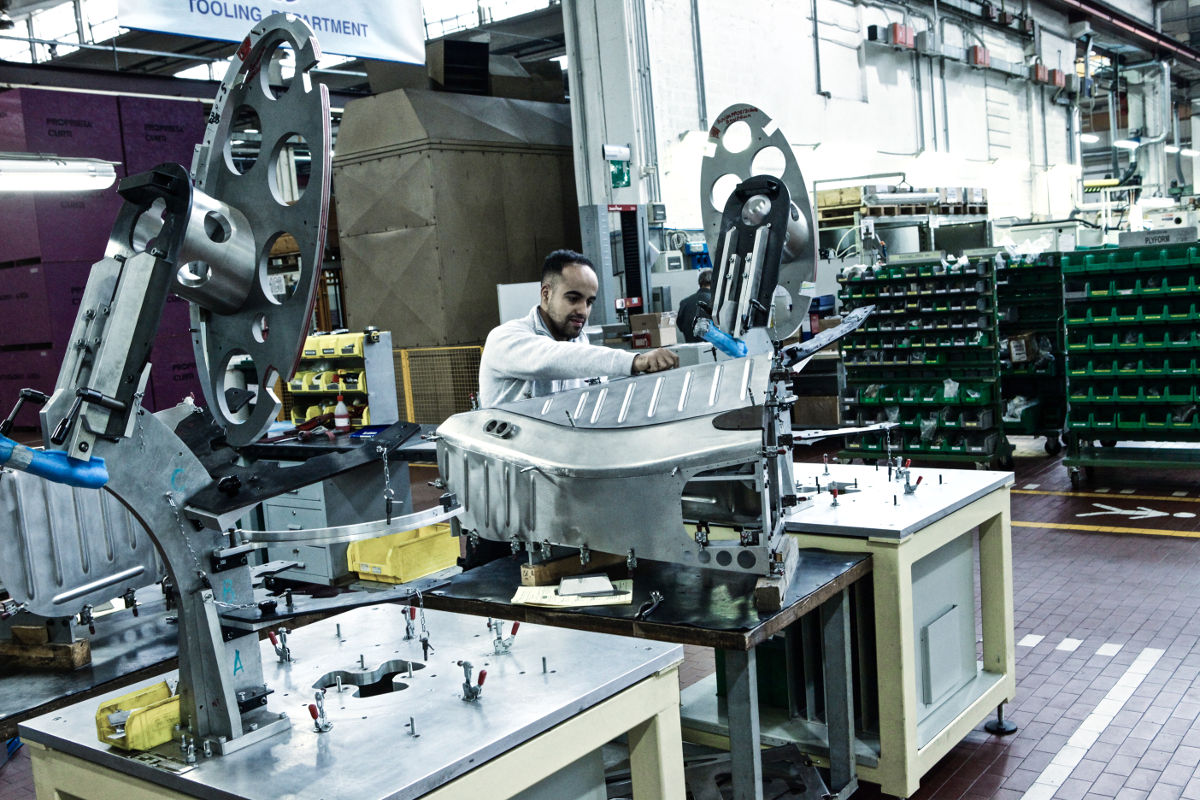

The division has solid experience in the design and manufacture of equipment for the production of parts and assemblies for helicopters, trainer aircraft and vehicles for transporting. We are capable of providing surface treatments such as chromate conversion coating for aluminium and steel passivation.

CURTI Aerospace has an internal workshop for quality control, equipped with the latest cutting-edge measuring technology and machines (CMM Zeiss). The division has ISO 9001, AS/EN 9100, ISO 14001, BS OHSAS 18001 certification and Nadcap accreditation for NDT and welding.

2024

QUALITY POLICY

2022

UNI EN ISO 9001:2015 Management systems for the Quality

2023

UNI EN 9100:2018 Management systems for quality organizations in the Air, Space and Defense

2016

UNI EN ISO 14001:2015 Environmental management systems

2024

ISO/IEC 27001:2022 – Management Systems for Information Security

2019

ISO 45001: 2018 Health and Safety management systems

2022

ISO 50001:2018 Management systems for Energy

2018

PART 21: Regulations UE n. 748/2012

2015

PIAGGIO AEROSPACE

2015

LEONARDO S.p.A. – Statement of Approval LH/0813

2020

TETRA PAK

2020

UNI EN ISO 3834-2 – Quality requirements for fusion welding of metallic materials

2024

DIN 2303 Certification – Fusion welding of titanium alloys, aluminum, steel

2023

NADCAP Accreditation – Nondestructive Testing (Magnetic Inspection – Penetrating Liquids)

2020

NADCAP Accreditation – Fusion welding of titanium alloys, aluminum, steel

2022

Leonardo Helicopters Qualification – Aluminum Heat Treatment

2022

Leonardo Helicopters Qualification – Chromate conversion of aluminum alloys

2024

Leonardo Helicopters Qualification – Passivation

2024

Leonardo Helicopters Qualification – Nondestructive Testing, Magnetic Inspection

2025

Leonardo Helicopters Qualification – Nondestructive Testing, Penetrating Liquids

2023

Leonardo Electronics Defence System Business Unit – Welding UNI EN ISO 3834-2

2024

Leonardo Helicopters Qualification – Resistance welding of titanium alloys, aluminum, steel

2020

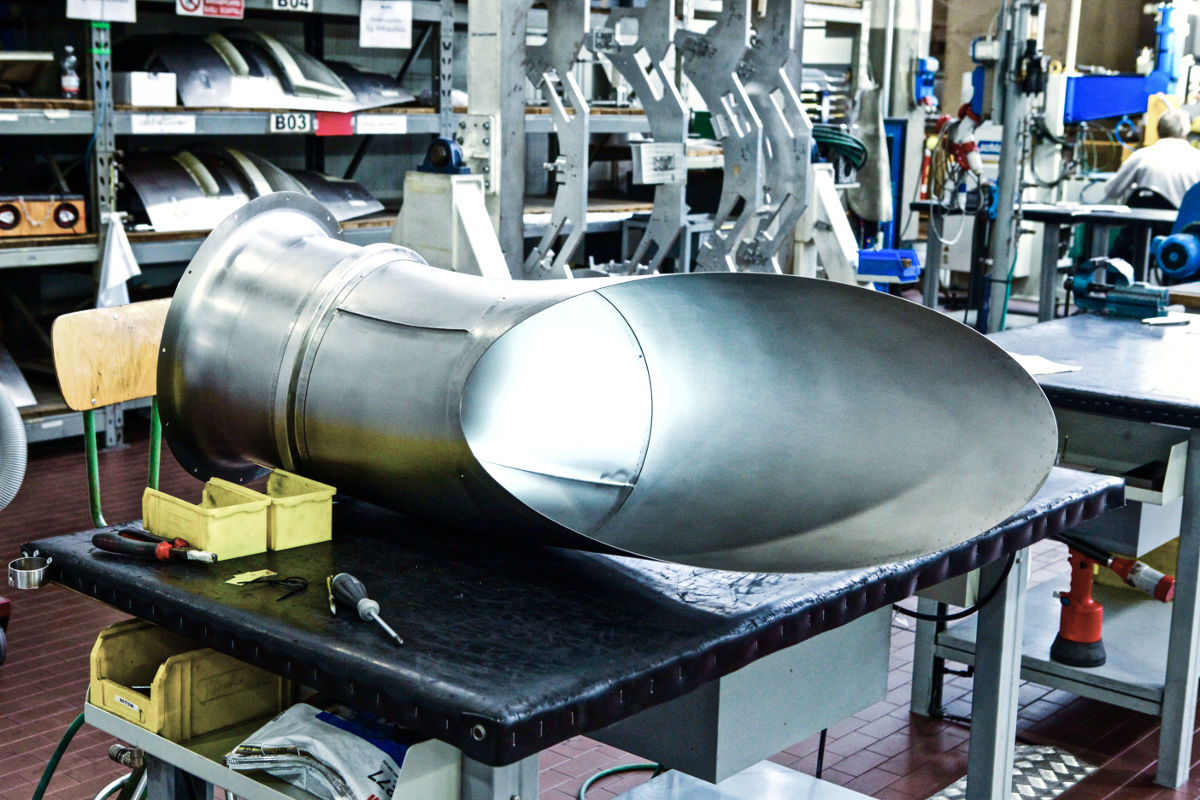

Leonardo Helicopters Qualification – Fusion welding of titanium alloys, aluminum, steelIn particular, in recent years, the division has specialised in the forming and processing of sheet metal for the aeronautic industry, using noble materials including high-strength stainless steel and special steels, aluminium alloys, pure titanium and titanium alloys, and special processes such as resistance spot welding, bonding and assembly of carbon fibre components.

The intermediate and final control of these processes is ensured through the use of various non-destructive control methods (on surfaces and volumes) applied by qualified personnel.

CURTI Aerospace has completely designed and built the first model of a totally innovative two-seater helicopter with a turbine engine. The development of the helicopter’s safety features is the result of a DISRUPT project, promoted by the European Commission as part of an important funding scheme for SMEs leading up to 2020.

CURTI is supported by UAVItalia into all the certification processes of the Zefhir helicopter.